Vehicle paint inspection in car body shops is evolving with advanced imaging systems and artificial intelligence (AI), increasing accuracy and efficiency. These technologies detect minute imperfections, streamline inspections, reduce manual labor, and minimize human errors, marking a significant advancement in automotive repair. AI-powered systems are expected to learn and adapt to various vehicle models and paint types, while augmented reality (AR) could offer real-time visual aids. These innovations aim to provide more efficient and accurate vehicle paint inspection for collision repair centers.

New devices are revolutionizing the field of vehicle paint inspection, addressing long-standing challenges in accuracy and efficiency. Traditional methods often fall short in detecting subtle defects, leading to subpar finishes. This article explores the current hurdles in vehicle paint inspection and delves into emerging technologies that are transforming this process. From advanced sensors to AI-driven systems, these innovations promise enhanced precision, faster turnaround times, and improved overall quality control.

- The Current Challenges in Vehicle Paint Inspection

- Emerging Technologies Enhancing Precision

- Impact and Future Prospects of Advanced Devices

The Current Challenges in Vehicle Paint Inspection

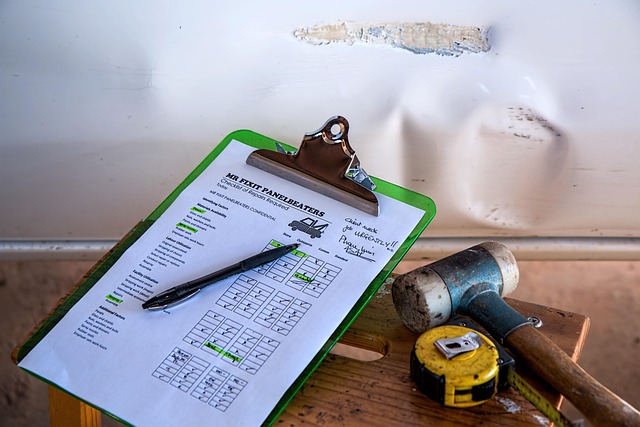

The process of vehicle paint inspection has traditionally relied on manual methods and human assessment, which can be subjective and time-consuming. In a car body shop or vehicle body shop environment, ensuring precise and consistent results is challenging due to various factors. Human inspectors may miss subtle imperfections, especially when dealing with complex finishes or difficult-to-reach areas of the vehicle. This inconsistency can lead to disparities in quality control, affecting the overall customer experience and the reputation of auto dent repair services.

Additionally, the current methods often require extensive training and specialized skills, making it a labor-intensive task. The complexity of modern vehicle designs, with their diverse paint finishes and special effects, adds another layer of difficulty. These challenges prompt the search for innovative solutions to enhance accuracy and efficiency in vehicle paint inspection, leading to advancements in technology tailored for car body shop operations.

Emerging Technologies Enhancing Precision

The world of vehicle paint inspection is witnessing a significant evolution thanks to emerging technologies that are enhancing precision and efficiency. Advanced imaging systems, coupled with artificial intelligence (AI), are now capable of detecting even the slightest imperfections on car bodies, from minor scratches to misalignments in painting. These innovations are not just improving the accuracy of inspections but also streamlining the process, reducing manual effort and potential human errors commonly associated with traditional methods.

One notable application is in automotive repair and car body restoration processes. Modern devices can swiftly identify issues that might go unnoticed during a manual inspection, enabling more effective fender repair or complete paint jobs. This level of precision not only ensures higher quality finishes but also saves time and resources for both manufacturers and repair shops.

Impact and Future Prospects of Advanced Devices

The advent of advanced devices has significantly revolutionized vehicle paint inspection processes, leading to a remarkable increase in accuracy and efficiency. These technologies, including high-resolution cameras, 3D scanners, and artificial intelligence (AI) algorithms, have transformed the way collision repair centers and vehicle bodywork specialists conduct their inspections. By offering detailed, non-destructive assessments, these devices have improved the precision of damage detection, especially in identifying subtle dents, scratches, and paint imperfections that might be overlooked by the human eye.

Looking ahead, the future of vehicle paint inspection appears promising with ongoing innovations. AI-powered systems are expected to become even more sophisticated, capable of learning and adapting to different vehicle models and paint types. This advanced technology will not only enhance accuracy but also streamline the entire process, reducing the time required for inspections. Moreover, the integration of augmented reality (AR) could offer real-time visual aids during repairs, enabling technicians to work with enhanced precision. These prospects suggest that collision repair centers can look forward to more efficient and accurate vehicle paint inspection and repair processes in the years to come.

Advanced devices, leveraging emerging technologies, are significantly improving the accuracy and efficiency of vehicle paint inspection. By adopting innovative solutions like high-resolution cameras, AI algorithms, and automated systems, the industry is moving away from manual, time-consuming methods. This not only enhances quality control but also reduces costs and turnaround times. As technology continues to evolve, we can expect even more precise and comprehensive vehicle paint inspection processes, setting new standards in automotive manufacturing and repair.